When you use a slurry pump to transport solid particles and liquids, sometimes some problems may arise, such as how to choose, install, and use a slurry pump.

However, there is no need to worry if you have these problems, because this article will show you how to choose, install, and solve the problems during use.

1.What Is Slurry Pump?

Slurry pump is a kind of centrifugal pump which can transport mixed solid liquid materials, it generates centrifugal force through the rotation of the impeller, and sucks the slurry containing solid particles into the pump body and conveys them to the place.

2. History Of Slurry Pump

In 1938, Charles Warman invented the slurry pump in Kalgoorlie, Australia. The pump originated primarily in mineral processing and transportation, and was developed through the modification of pumps. Has been from the initial low efficiency, slow conveying, conveying distance is limited, easy to damage, to the present more rugged, more durable materials, more scientific centrifugal pump and hydraulic design, can be larger capacity and longer distance conveying, widely used in mining transportation, mineral processing and dredging and other places to convey corrosive and high-density slurry.

3. How Does Slurry Pumps Works?

The working principle of slurry pump is mainly based on the role of centrifugal force.

Slurry pump by the motor, drive shaft, impeller, pump casing, stirring impeller and other components, the motor starts to drive the impeller and stirring impeller high-speed rotation, through the rotation of the slurry pump impeller, the pump casing produced a centrifugal force. Under the action of centrifugal force, the liquid is thrown to the edge of the impeller, the formation of high-speed rotation of the liquid ring, so as to realize the transport. At the same time, due to the pressure reduction in the center part of the impeller, a vacuum area is formed, which allows the liquid to be continuously sucked into the pump body.

At the edge of the impeller, the high speed rotating liquid gradually expands the flow channel through the worm gear structure, which reduces the flow velocity and increases the pressure. In this process, part of the kinetic energy is converted into static pressure energy, the liquid can flow out of the pump body at high speed. At the same time, due to the special characteristics of the pump body’s worm gear structure, the liquid can form a rotating angle when it flows out of the pump body, which is favorable for the transportation of the liquid.

4.What Are Slurry Pump Made Of ?

The slurry pump is composed of the following materials: 25-28% chromium, rubber, polyurethane, stainless steel 316/304, ductile iron, ceramics. Here are some of the main components.

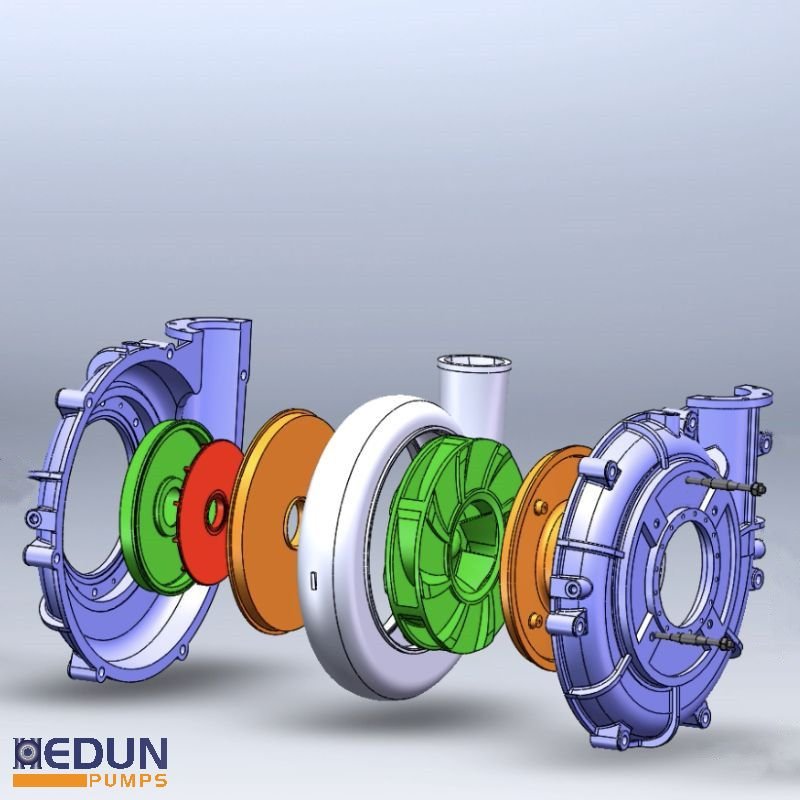

4.1 Slurry Pump Parts

Slurry pump components. Typically includes motor, impeller, worm housing bushings, throat bushings, cover plate bushings, frame plate bushings, bearing assemblies, and more.

4.2 Slurry Pump Engine

Depending on the specific situation and conditions, different engines can be selected, such as electric motors or diesel engines. The electric generator type is a three-phase electric motor, usually with a voltage of 380V-6600V, which can be directly controlled by speed and torque using a variable frequency drive. Diesel engines are usually used in heavy-duty applications because of their higher power output and portability, and can be used in remote areas without electricity.

4.3 Slurry Pump Bearing

Bearings are an important part of slurry pumps. Slurry pumps are usually made up of 2-3 rolling bearings, which reduce friction by rotating the bearings against other components.

The basic part number of the slurry pump bearing is 009, and its function is to limit the shaft to rotate only in the bearing box.

Warman pump bearings belong to the rotating part of the slurry pump, mainly used with bracket, shaft, bearing box, bearings, labyrinth sleeve, labyrinth ring and so on.

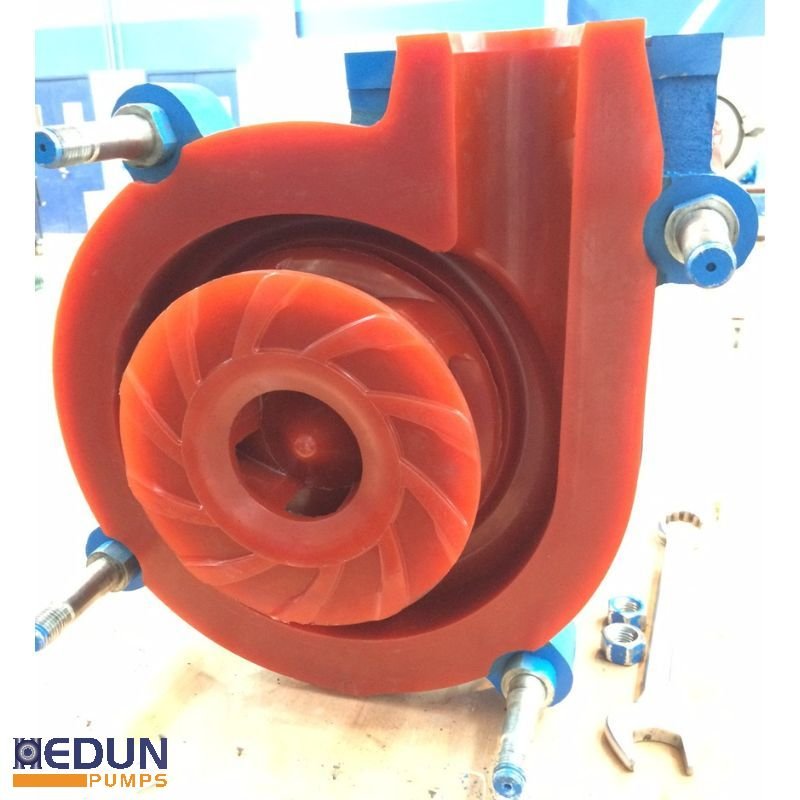

4.4 Slurry Pump Impeller

Impellers are an important component of slurry pumps. Impellers are designed for applications where the passage of solid particles is smoother and erosive wear is minimized.

Warman slurry pump impellers are mainly made of high chrome alloy, natural rubber, A49, polyurethane, Cr30, silicon carbide ceramic, etc. The main pumps are AH series slurry pumps, G-type gravel pumps, and AHR rubber slurry pump impellers.

Warman slurry pump impeller has closed impeller, semi-open impeller, open impeller.

1, closed impeller: by the blade and the front and back cover plate composition. Closed impeller’s efficiency is higher, manufacturing difficulty. In the centrifugal pump in the most applications. It is suitable for conveying clean water, solution and other clean liquids without particles with small viscosity.

2, semi-open impeller: generally there are two kinds of structure of its first half-open, by the back cover plate and vane composition, this structure impeller efficiency is low, in order to improve efficiency need to be equipped with adjustable gap sealing ring another half-open, by the front cover plate and vane composition, due to the application of the same sealing ring with the closed pump impeller? Efficiency and closed impeller is basically the same, and the blade in addition to transporting liquids, but also has: the back blade or the sealing effect of the secondary impeller.

3, open impeller: only blade and blade reinforcement, no front and back cover impeller. Open impeller blade number is less 2-5 pieces. Water pump impeller efficiency is low, less application, mainly used for conveying high viscosity liquid and slurry liquid.

4.5 Slurry Pump

Slurry pump is an important part of the slurry pump transportation system, slurry pump is a kind of pump that can transport particles of fluid, different from the design of the pump, the slurry pump has been specially treated to transport corrosive with a large number of particles of slag, wood chips, mud and so on.

4.6 Slurry Pump Seals

Slurry pump seals. Slurry pump seals can resist damage from sand, sludge, limestone, wastewater, mud, etc., effectively extending the life of the system.

Here are three kinds of sealing: 1.

1. packing seal: this is the most common type of sealing. It is the most common type of sealing, it is in the shaft seal at the packing 4 packing, now by the water sealing ring, packing box, positioning sleeve and other accessories composed of sealing components.

2. Pay impeller + packing seal: this is also slurry pump commonly used a sealing method. It is by pay impeller + 2 packing composition. Mainly rely on and the main impeller synchronization pay impeller pressure to prevent slurry leakage.

3. Mechanical seal: Mechanical seal is commonly used in the site with high requirements for sealing. It can do completely no leakage. Its structure is relatively simple, that is, by the mechanical seal, machine seal box, machine seal bushing seal assembly.

5.Types Of Slurry Pump

5.1 Warman Slurry Pump

The Warman pump, as we often refer to it, is a slurry pump invented by Charles Harold Warman of Australia, who patented the replaceable rubber lined pump in 1938, which was the origin of the double casing slurry pump. The pump was also known in the industry as the Warman pump.

Warman pumps were later acquired by the Weir Group. Weir Minerals is a leader in the slurry pump industry and owns the world famous Warman slurry pump. Warman pump is a global universal pump brand, each part has a unique number, is a high-pressure centrifugal pump, can transport corrosive slurry, mainly used in mineral processing plants, coal plants and other scenarios, so it is also known as mining slurry pumps, coal slurry pumps and so on.

Warman pump is a global brand of universal pump, each part has a unique number, is a high-pressure centrifugal pump, can transport corrosive slurry, is used in mineral processing, petroleum, chemical, river dredging and other fields.

5.2 Horizontal Slurry Pump

Horizontal slurry pumps are centrifugal pumps that are designed to transport suspended particles, heavy and corrosive slurries. Horizontal slurry pumps are composed of robust materials that can withstand prolonged friction with solids.

5.3 Vertical Slurry Pumps

Vertical slurry pumps are specially designed for corrosive slurries, its wear parts are made of hard metal or rubber, the main transportation nap you as well as machine tools for wood chip conveying.

6.Application Of Slurry Pump

6.1 Slurry Pump Market Size

The market size of slurry pumps is growing at 10% over 10 years from USD 1.1 billion in 2023. With a CAGR of 1.6%, it is an incremental market. Slurry pumps are pumps specially designed to transfer liquids containing suspended solid particles. The slurry pump market serves end-users in industries such as water treatment, mining, and metallurgy.

6.2 Slurry Pump Calculation

Accurate calculations ensure efficient pump utilization and longevity.

The calculation procedure is as follows.

Step 1: Determine the flow rate

Step 2: Calculate the head

Step 3: Calculate the density of the slurry.

Step 4: Calculate the power

Step 5: Check the specific gravity to ensure that the specific gravity of the slurry is suitable for the operating limit of the pump.

6.3 Slurry Pump Pressure

The following factors, can affect the slurry pump pressure factors are many,

- Slurry density and viscosity. Higher density and viscosity slurries increase the pressure required to pass through them.

- Pump type and design. Centrifugal pumps have higher pressure and efficiency.

- Impeller design. The shape, size and speed of the impeller will affect the head.

- Piping. The length, diameter, width and shape of the piping affects the pressure.

- Particle concentration. The higher the concentration, the higher the friction and the higher the pressure required.

6.4 Slurry Pump Application

Application of slurry pumps.

Slurry pumps can be used in a wide range of applications, such as highly abrasion-resistant environments and corrosive liquid environments, as required. These include, but are not limited to, the following applications.

- Coarse sand

- Tailings

- Dredging

- Heavy media

- Chemical fluids

- Wastewater

- Pulp & Paper

6.5 Slurry Pump Working Principle

Slurry pump working principle. Slurry through the impeller eye into the slurry pump, the impeller began to move. Slurry in the centrifugal force began to move outward, slurry smoothly through the slurry pump, into the pipeline.

7.How To Choose Right Supplier ?

The main factors to judge the slurry pump suppliers are: delivery time, product quality, inventory level, product design ability, after-sales service and so on.

And the quality and price of the products supplied by the slurry pump suppliers determine the quality and price of the final consumer goods, which affect the market competitiveness, market share and market viability of the final products, as well as the core competitiveness of the components of the supply chain.

7.1 Slurry Pump Manufacturers

Consider the following when considering a supplier.

- Product quality and reliability. Quality products have a strong value of use, it determines the quality of the final consumer goods, affecting the competitiveness of the product market and share, so quality is the primary factor in the selection of slurry pump suppliers.

- Product standards, technical support and professional support. High-quality after-sales service not only can quickly answer your questions, and can be customized according to your needs for you to solve the problem. There are many slurry pump suppliers in order to hold customers, will change the size of individual parts, so that customers can not change suppliers, so before you buy should ask whether the standard size parts.

- Price factor: the price factor is an important factor for customers to consider, but the price is not necessarily the only factor, it should be considered together with product quality, delivery and after-sales service.

- Delivery: whether the agreed time and place will be on time delivery of products, directly affecting the continuity of customer production, but also when choosing slurry pump suppliers of necessary factors.

- Pre-sales technical support and after-sales technical support. In addition to the above factors, but also consider the customer may need to buy the technical aspects of the guidance, there is no complete operation manual and personnel support, to ensure that you buy before and after the purchase, there are people to solve the technical aspects of the problem. This is also a very important factor.

- Design capability, sometimes different use scenarios, budgets, functions, there will be unique needs, according to these different needs to design, to meet the unique needs of the product. Companies that can design and produce are in a better position to do so.

7.2 Slurry Pump Leading Brands

There are many famous brands to choose from, such as: Weir Group, Metso, ITT Goulds pump, Flowserve, KSB, Xylem, Shijiazhuang Industrial Pump, Shijiazhuang Kingda Pump, Shijiazhuang Hedun, Schurco Slurry

FAQ

1.What Is Slurry Pump Also Known As?

Slurry pump, also known as liner pump or dredge pump, it is a kind of centrifugal pump, mainly used to transport solid fluids with high abrasion resistance and corrosiveness, such as suspended particles, slag, tailings, gravel and so on.

2.Slurry Pump Specifications,The Main Technical Parameters When Choosing Slurry Pumps Are As Follow

| Pump TypeHorizontal ☑️Vertical ☑️ | General ConditionsData | ||

| Flow Rate | = m3/h | Slurry temperature | = ℃ |

| Total Differential Head | = mlc | PH value | = |

| Slurry Density | = kg/m3 | Concentration by Weight | = % |

| Concentration by Volume | = % | ||

| Suction Side Conditions | Duty Data | ||

| Suction Head | = mlc | Abrasive or Corrosive | = |

| NPSH Available | = mlc | ||

| Solids Data | Site Conditions | ||

| Max. particle size d100 | = mm | Altitude | = m |

| Particle size d50 | = mm | Ambient Temperature | = ℃ |

| Solids Density | = kg/m3 | Voltage | = V |

| Frequency | = HZ | ||

| Liquid Data | |||

| Liquid Viscosity | = Pa.s | ||

| Vapour Pressure | = m wc | ||

| Liquid Density | = kg/m3 |

3.What Is The Disadvantage Of Slurry Pump

One of the disadvantages of slurry pumps:Purchase cost and maintenance cost is higher than other types of pumps,easy to clog,need frequent inspection and maintenance.

Because of the use of harsh environment, the overflow parts wear fast, need to replace the overflow parts often, if the replacement is not timely, it may cause stoppage of work and production, increasing costs.

4. The Benefit Of Slurry Pump Vs Water Pump?

1) Water pumps only transport water and other liquids, and slurry pumps transportmedia containing granular materials, such as ore, gangue and so on.

2)Slurry pump more wear-resistant, cast iron based on the addition of traceelements, added 27% of chromium (chrome), can resist the high concentration ofslurry on the pump body to wear and prolong the service life.

3)Slurry pump impeller channel is wider, easy to transport suspended solidparticles, while the pump can only transport sewage and other liquids.

4)Slurry pump is thicker, heavier, more solid. And the pump is relatively thin, lightweight.

5.What Are The Factors That Affect The Service Life Of The Slurry Pump?

- No reasonable design

Slurry pump in the production and manufacturing process, if there is no reasonable design, or there are design defects, the future will affect the stable operation of the slurry pump. In the process of use, for the design defects, even if the local adjustment or increase the number of maintenance, it is difficult to completely discharge the problem. In the irrational design of operation, there will be a short life. The more common unreasonable: design structure is unreasonable, appear slurry pump running abnormal; Water conservancy design problems, cause slurry pump slurry can not be effectively integrated.

- Slurry pump wear

Slurry pump is mainly transported solid particles and liquid mixture, so solid particles will increase the wear and tear of the slurry pump. In the conveying process, the slurry pump overflow part of the wear is the most serious. As a result of the direct impact of solid particles, impeller bearing seals and other components will also be subjected to wear, slurry pumps so that the cavitation phenomenon will produce noise and vibration, so that the flow becomes smaller, lower head, power becomes weak and other phenomena, shortening the service life. Cavitation phenomenon is the most fatal factor affecting the service life of the slurry pump.

- Slurry concentration is too high

The service life of the slurry pump is largely affected by the concentration of the slurry. Each type of slurry pumps are specified to transport the maximum slurry weight, concentration and maximum particles. If the slurry concentration is too high, does not meet the requirements of the slurry pump parameters, will cause the feed pipe resistance is too large, and even back to damage the slurry pump overflow components and other parts.

- Selection

Reasonable selection of slurry pump is to ensure that the slurry pump service life is an important factor. Reasonable selection can ensure that the slurry pump running stable, in the selection of general use of some formulas to calculate the head and other parameters, reasonable selection, can ensure that the slurry pump reasonable use of the scene and service life.

- Slurry pump quality

Overflow parts are the core components of the slurry pump, its material determines whether the slurry pump is wear-resistant, and the core point here is the chromium content, if the chromium content is not up to standard, it will make the weight lighter, at the same time it will lead to the flow of parts wear and tear very fast.

In summary, there are many factors affecting the service life of the slurry pump, product quality, working environment, selection, design are factors affecting the service life, but as long as according to the needs of the choice of reasonable manufacturers and suitable selection, coupled with regular maintenance, found that the problem is solved in a timely manner, I believe that the slurry pump will have a very good service life.

6.The Price Factors

Slurry pump market, novice buy pumps generally do not know how to choose, I am here to simply analyze the impact of slurry pumps a few factors to facilitate everyone from the wide variety of prices and a large number of manufacturers to find the one that suits you.

- Selection of slurry pump.

According to the working conditions, there are many optional slurry pumps, for example, you can choose ZJ series of horizontal slurry pumps, you can also choose AH horizontal slurry pumps (warman slurry pumps), you can also choose ZGB heavy duty slurry pumps. Price ranking is ZGB>ZJ>AH

- Material of slurry pump accessories

The material of the slurry pump is high chromium wear-resistant alloy, most manufacturers use this material, choose this material, the price basically will not have big fluctuations.

- The weight of the slurry pump accessories

Slurry pump fittings in the wearing parts (sheath, left and right guard, impeller) design weight is based on a combination of factors to consider and design, if you reduce these weight, will shorten the service life. For example, from 120 kilograms to 100 kilograms.

- Slurry pump fittings processing technology and assembly technology

Slurry pump fittings belong to high-precision technology, if the precision is not enough in the use of the process will be a lot of problems. Slurry pump debugging is very critical, slurry pump dynamic balance and static balance debugging and overall slurry pump debugging, are very fine, need to spend a lot of personnel and tools to become qualified products, and some manufacturers will be because of time, money factors omitted debugging link.

Conclusion:

In summary, slurry pump plays an important role in many fields. This guide provides an in-depth analysis of the different types of slurry pumps, the history of pumps, market capacity, pump components and materials, and how to choose suppliers. It is the ultimate reference for purchasing and operational decisions .